Electrical estimating is a critical process in the construction industry. It involves calculating the costs of electrical projects accurately, which ensures that the project can be completed on time and on budget. In this comprehensive guide, we will discuss the basics of electrical estimating, including the key terms and concepts used in electrical estimating, the electrical estimating process, types of electrical estimating methods, electrical estimating tools and software, reading and interpreting electrical blueprints, estimating materials costs for electrical projects, and estimating labor costs for electrical projects.

Key Terms and Concepts Used in Electrical Estimating

To begin with, it is essential to understand the key terms and concepts used in electrical estimating. Here are a few of the most important ones:

Takeoff – The process of measuring and quantifying the materials required for a project, such as wire, conduit, and fixtures.

Unit cost – The cost per unit of a particular item, such as the cost per foot of wire.

Markup – The percentage added to the total cost of the project to cover overhead and profit.

Estimating – The process of determining the cost of a project.

Budgeting – The process of allocating funds for a project.

Now that we have defined some of the key terms and concepts, let’s explore the electrical estimating process.

The Electrical Estimating Process

The electrical estimating process involves several steps that must be followed to estimate the cost of a project accurately. These steps include:

- Initial Assessment – The first step is to assess the project’s scope and the client’s requirements. This involves reviewing the project’s specifications and blueprints, conducting a site visit, and discussing the project with the client.

- Takeoff – Once you have a thorough understanding of the project’s requirements, the next step is to perform a takeoff. This involves measuring and quantifying the materials required for the project, such as wire, conduit, and fixtures.

- Estimating Material Costs – After the takeoff is complete, the next step is to estimate the cost of the materials required for the project. This involves calculating the quantities of materials required, as well as their unit cost.

- Estimating Labor Costs – In addition to material costs, it is also essential to estimate the labor costs for the project. This involves calculating the number of hours required to complete the project, as well as the labor rate for each worker.

- Overhead and Profit – Once the material and labor costs have been estimated, the final step is to add overhead and profit. This is typically done as a percentage of the total project cost.

Types of Electrical Estimating Methods

There are several different types of electrical estimating methods, each with its pros and cons. These include:

- Unit Price Estimating – This method involves estimating the cost of each item required for the project, such as wire, conduit, and fixtures. The total cost is then calculated by multiplying the unit cost by the quantity required.

- Lump Sum Estimating – This method involves estimating the total cost of the project as a single lump sum. This is typically done when the project’s scope is well-defined, and there is a high level of certainty regarding the costs involved.

- Time and Materials Estimating – This method involves estimating the cost of the project based on the time and materials required to complete the work. This is typically used for smaller projects, where the scope and requirements are not well-defined.

Electrical Estimating Tools and Software

In addition to the above methods, there are several tools and software available for electrical estimating. These include:

- Excel Spreadsheets – Excel is a powerful tool for estimating the cost of electrical projects. It allows you to perform takeoffs, estimate material and labor costs, and calculate overhead and profit. It also allows you to create detailed reports and estimates that can be easily shared with clients.

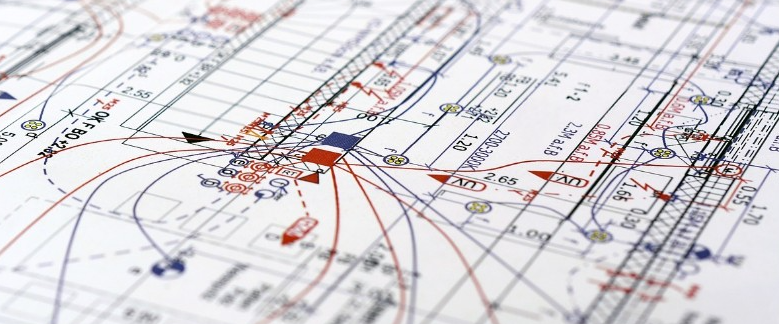

- Reading and Interpreting Electrical BlueprintsAnother critical aspect of electrical estimating is reading and interpreting electrical blueprints. Electrical blueprints provide detailed information about the electrical components and systems required for a project. Here are some tips for reading and interpreting electrical blueprints:

- Understand the symbols and conventions used in electrical blueprints. This includes symbols for switches, receptacles, and circuit breakers, as well as conventions for wire sizes and colors.

- Pay attention to the scale of the blueprint. This will help you determine the sizes of components and the lengths of runs.

- Look for notes and callouts that provide additional information about the project.

Estimating Materials Costs for Electrical Projects

Estimating the cost of materials for electrical projects can be a complex process. Here are some tips for estimating materials costs:

- Use accurate measurements and quantities. This will help you avoid overestimating or underestimating the amount of materials required.

- Consider the cost of specialty items, such as high-end light fixtures or specialized wiring.

- Account for waste. This is particularly important when estimating the cost of materials like wire and conduit, which may have scrap or cutoffs.

Estimating Labor Costs for Electrical Projects

Estimating the cost of labor for electrical projects is another critical aspect of electrical estimating. Here are some tips for estimating labor costs:

- Calculate the number of hours required to complete the project. This will depend on the scope and complexity of the project.

- Consider the labor rate for each worker involved in the project. This may vary depending on their level of experience and expertise.

- Account for overhead costs, such as insurance, taxes, and benefits.

Conclusion

In conclusion, electrical estimating is a critical process in the construction industry that involves calculating the costs of electrical projects accurately. By following the tips and strategies outlined in this guide, you can ensure that your electrical estimating is accurate and effective. Whether you are a seasoned estimator or just starting in the field, understanding the basics of electrical estimating is essential for success in the construction industry.

Estimating Software – There are several specialized electrical estimating software programs available that can simplify and streamline the estimating process. These programs can perform takeoffs, estimate material and labor costs, and calculate overhead and profit. They also allow you to create detailed reports and estimates that can be easily shared with clients.